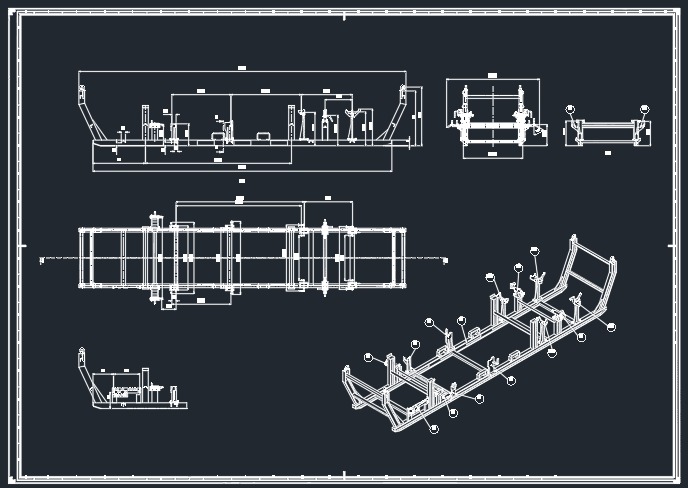

Efficiency and precision are essential elements in the operation of an automobile plant. Among the many components that play crucial roles in this environment, the skid stands out as a true pillar of logistics, ensuring not only the proper transport of the bodies, but also the precise positioning of the products at various stages of the production process.

Expertise in the use of skids extends from initial design to final installation, ensuring that each skid is built to the highest standards of quality and precision. The commitment to excellence ensures that each skid manufactured maintains stable performance over time, contributing to the efficiency and continued success of automotive operations.

There is a wide range of skids available, from the simplest intended for transportation to the most specialized, designed to meet the specific needs of each production line. Whether for surface treatments during the painting process or for specific geometries on welding lines, it is possible to provide tailor-made solutions that meet the individual demands of each customer.

While skids play a crucial role in automotive logistics, it’s important to recognize that the technology is constantly evolving. Nowadays, AGV (Automated Guided Vehicles) systems are also gaining prominence. Not only do these automated vehicles transport components along the production line, but they also have the ability to move from one side to the other, dynamically adjusting to the needs of the production process.

Being aware of these innovations is key to integrating even more efficient and adaptable solutions into automotive production.

If you are looking for quality and reliable skids to optimize your automotive operation, do not hesitate to contact us by email comercial@carraroproject.com.br.

We’re here to help you achieve your production goals safely and efficiently.